We  are glad to introduce ourselves as a Third party Inspection agency and Quality Consultant in Karachi, Pakistan established in 2004 doing Final Inspections, Quality consultant, Conducting Quality trainings, Implementing production and quality systems in the factories.

are glad to introduce ourselves as a Third party Inspection agency and Quality Consultant in Karachi, Pakistan established in 2004 doing Final Inspections, Quality consultant, Conducting Quality trainings, Implementing production and quality systems in the factories.

Our organization is engaged in offering high end Third Party-Inspections services that help in improving the product quality, with a reduction in client complaints, non-compliance and product recalls. Supported by a team of expert professionals, these inspection procedures are designed and developed to offer hassle free experience to clients. Offered at most competitive prices, our inspection services include Our Quality technicians are Apparel Graduates and having more than 14 years of experience in the Inspection field with vast knowledge of International standards.

We are familiar & specialized in Knits, Woven fabric, garments home Textile, Socks, leather and sports goods raw material and finished goods inspection services.

We hold expertise in rendering reliable and effective Textile Inspection Services that ensure delivery of products created as per buyer and seller agreement. In addition, they incorporate 10 point & 4 point System for Greige/Finished Fabrics of woven/knitted varieties or any other specified standards.

Further, the team analyzes the standard specified attributes with product's features including a wise verification or final verification (FRI) procedure. It can be summarized as:

PPI - Pre Production Inspection:

Performed on the size set, the inspection procedure stringently verifies the garments for size measurement conformity against specified measurement and the workmanship quality.

IPI - Initial Production Inspection:

Carried at the initial level of the manufacturing, this Inspection includes verification of ready 20 to 50 pieces against basic product specification, like measurement and workmanship.

MPI - Mid Production Inspection:

The following inspection procedure is performed at the stage of production where 30 to 50% of the ordered quantity covering all colors and sizes are ready and see that initial discrepancies have been rectified. Moreover, corrective measures has been implemented and also checked for measurement and workmanship.

FRI - Final Random Inspection:

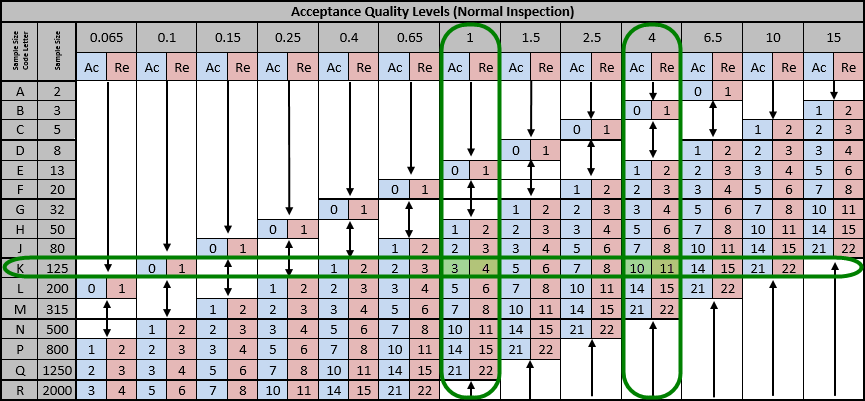

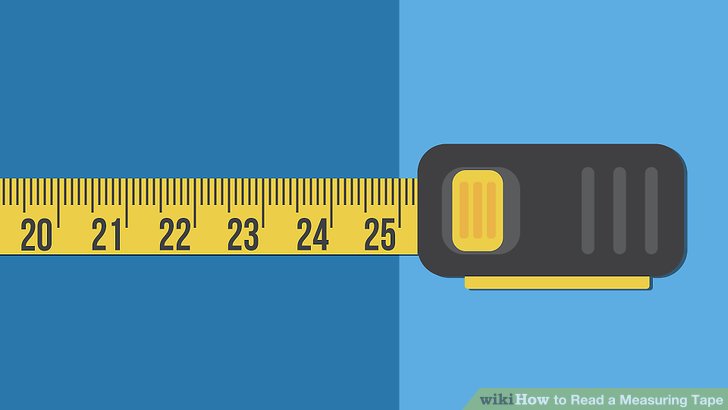

This Inspection is performed at the end of production where the goods are ready for shipment in fully packed condition as per contractual requirement based on AQL Levels.